BNA series Single Stage, End Suction Norm Centrifugal pumps

Remarks:

We have been OEM for many brands from Europe and our pumps has been used by famous brands from Middle east to apply for UL/FM Certificate. We can make pumps with the bearing housing as your own design.

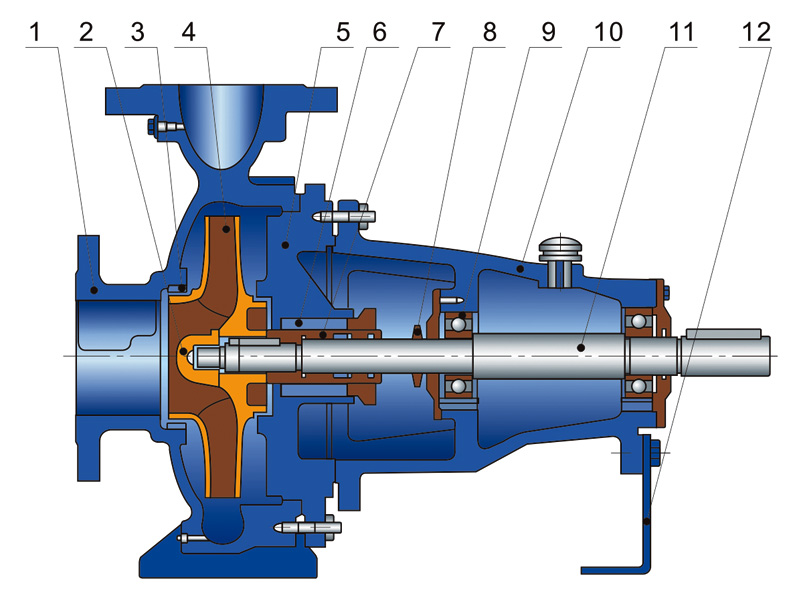

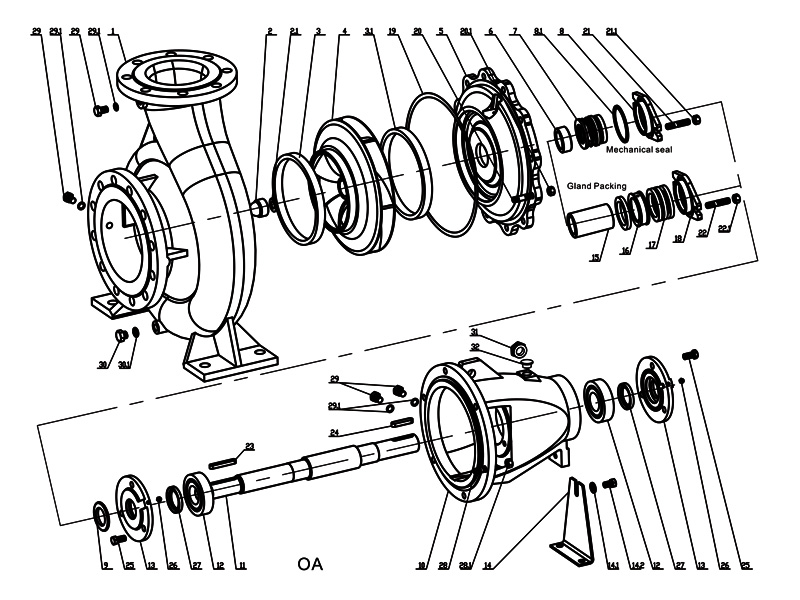

Constructure

| 1 | Casing | 17 | Gland Packing |

| 2 | Impeller Nut | 18 | Gland Cover |

| 2.1 | Lock Washer for impeller | 19 | Paper Casing Gasket |

| 3 | Front-Wear Ring | 20 | Stud Bolt |

| 3.1 | Back Wear Ring | 20.1 | screw nut |

| 4 | Impeller | 21 | Stud Bolt |

| 5 | Casing Cover | 21.1 | screw nut |

| 6 | Shaft Spacer | 22 | screw nut |

| 7 | Mechanical Seal | 22.1 | Stud Bolt |

| 8 | Seal Cover | 23 | key |

| 8.1 | "O"Seal Ring | 24 | key |

| 9 | Rubber Slinger | 25 | screw bolt |

| 10 | Bearing Housing | 26 | oil nipple M6 |

| 11 | Shaft | 27 | Oil seal |

| 12 | Bearing | 28 | Stud Bolt |

| 13 | Bearing Cover | 29 | Plug |

| 14 | Support Foot | 29.1 | Plug spacer |

| 14.1 | screw bolt | 30 | Plug |

| 14.2 | screw nut | 30.1 | Plug spacer |

| 15 | Packing Sleeve | 31 | oil Scale |

| 16 | Packing seal Cage | 32 | Oil Cup |

>>>>>Description:

• End suction, Volute type with top centerline discharge suction and discharge nozzles as well as the supporting feet are cast integral with the casing The working pressure up to 1725kpa( 18kg/cm2), testing pressure is more than 1. 5 times of the working pressure suitable for NFPA20.

>>>>>Casing:

• All cast iron casting is made of Alluminum Moulding (no wooden or sand moulding) and all SS casting is made of Investment/lost wax moulding Enclosed type and accurately balanced dynamicall Hydraulically balanced by back vanes and for large impellers by balancing holes and back wear ring.

>>>>>Impeller:

•Enclosed type and accurately balanced dynamicall.Hydraulically balanced by back vanes and for large impellers by balancing holes and back wear ring.

>>>>>Shaft

• Four driving units cover complete range. The high tensile steel shaft accurately machined and groud is supported by antifriction bearings. The shaft is protected by shaft sleeve from wearing in the stuffing box area.

>>>>>Stuffing Box

• The stuffing box can be sealed by gland packing or by mechanical seal.

>>>>>Bearing

• Deep Groove ball bearings or contact bearing are provided.

• Standard lubrication is grease.

• Oil lubrication against requirement.

DIN 625: Single Deep Grove Ball Bearing

(Axial Force)

DIN628: Double Angular Contact Ball Bearing

( Both Radial+Axial Forces)

DIN 5412: Cylindrical Roller bearing

(High Radial Forces)

• The bearings comply with AFBMAB-10 Standard, the service life is up to 100,000 hours.

• And The bearing can be ZZC3 type.

(normally 6305ZZ, 6307ZZ, 6309ZZ, 6311ZZ, etc)

>>>>>Mechanical Seal

• 32mm/24mm,43mm/32mm,53mm/44 mm

• The max operation temperature is up to l07℃

• The max working pressure is up to 1 8kg/cm2

• Material of mechanical seal:

Carbon-ceramic/Nbr

Carbon-ceramic/Viton

Silicon carbide/silicon carbide/viton

Silicon carbide/silicon carbide/Teflon

>>>>>Flange

• ISO2084-16bar(BS4504-1969 Table 16/11)

• DIN2332 PNIORF, Optional ANSI B16.5 Class 300lb.

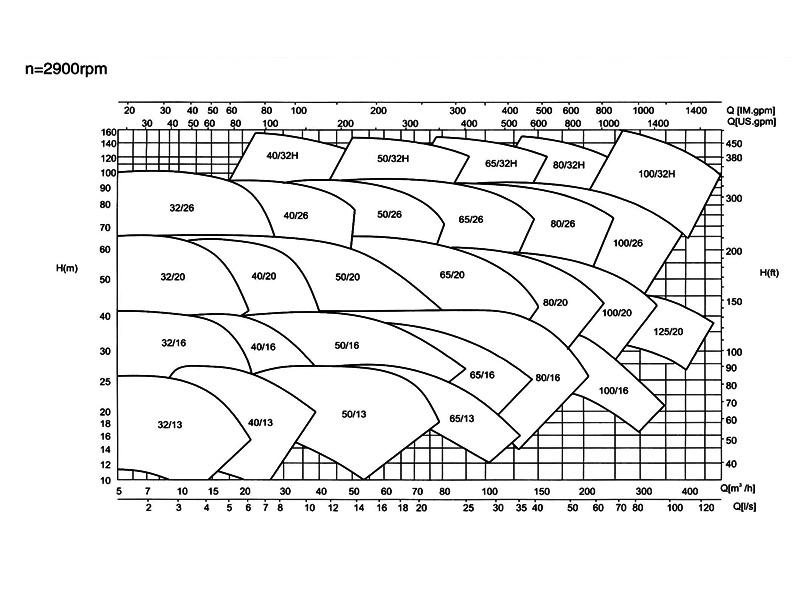

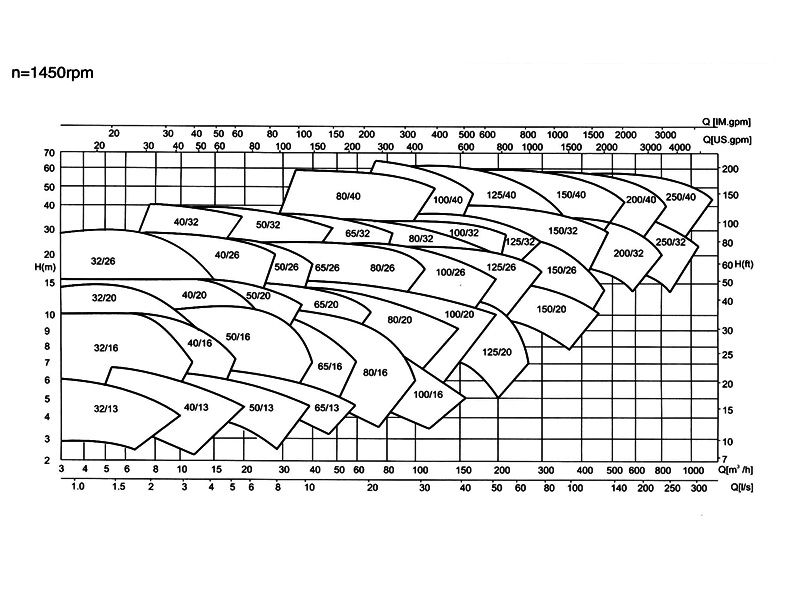

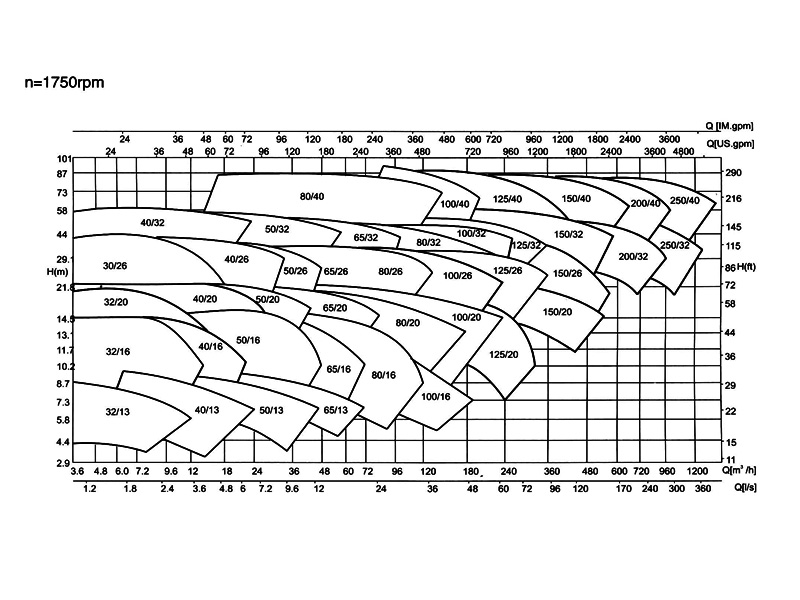

>>>>>Technical Data:

• Flow:2-1100m3/h

•Head:2-150m

• Speed: 1450rpm/2900rpm(50Hz)

1750rpm/3500rpm(60Hz)

• Temperature:-10C--150

• Operating Pressure: 10Bar, Optional 16Bar.

>>>>>Application:

•City Water Supply •Irrigation •Fire Fighting •Air conditioning•Fresh water on the ship •Sanitary and cleaning installation •Power Sation•Mine Drainage•Spinkler system •Brine Pumping •Alkaline solution•Oil and Benzene