BSP Vertical slurry pumps

BSP Vertical slurry pumps are 100% fully interchangable with the most common slurry pumps design in the mining industry.

This Heavy duty range features a cantilever shaft design that elimiates any bearings or seal in the fluid end

And idea pump for heavy slurry wash down and spill duties

A full range of material options including complete elastomer lined pumps and hard metal options for corrosive and abrasive media duties. Pumps in all sizes can be configured with a range of collumn lengths and impeller designs. Ideal for corrosive coarse particles and high concentrations of slurry and are widely used in metallurgical, mining and coal industries.

Our slurry pumps use the liner of Corundum materials containing aluminium oxide Al2O3 95-99.5%,and casted in the temperature higher than 1700 ℃ with hardness of 80-90 HRC. And casing and casing cover is using the ceramic liner shrouded with ss frame, the wearing character is 266 times of Mn Steel and 171.5 times of High Chrome.

The service time of the pumps can be 5 times than the pumps under same conditions.

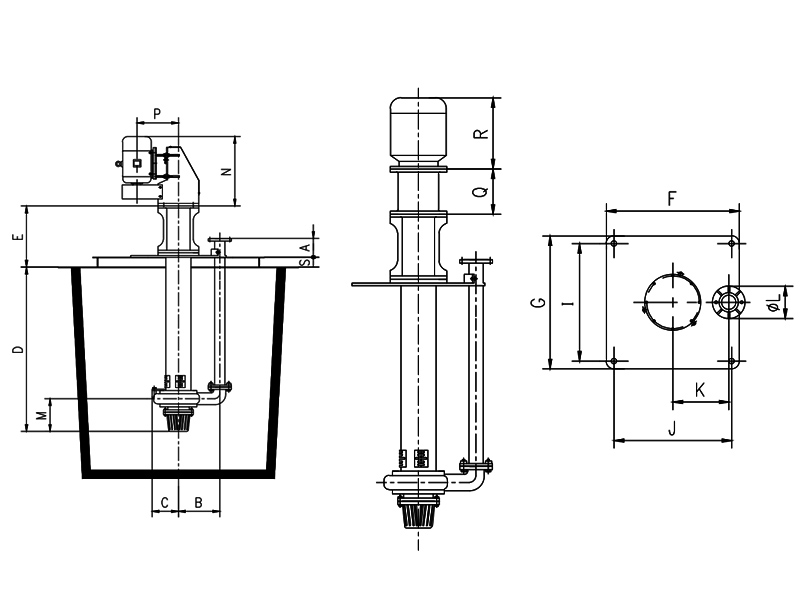

Sectional Drawing

CANTILEVERED SHAFT EXTENDED SHAFT

| Description | Standard Material | Material Options |

| Shaft | 4140 Mild Steel | Available on Request 1 |

| Bearing Housing | Cast Iron | |

| Column | Mild Steel | |

| Upper Strainer | Rubber | Cast Iron |

| Lower Strainer | Cast Iron | |

| Back Liner | 27% Chrome White Iron | |

| Pump Casing | 27% Chrome White Iron | Rubber Lined White Iron |

| Impeller | 27% Chrome White Iron | Rubber |

| Discharge Pipe | Mild Steel | Rubber Lined Mild Steel / Composite |

| Adaptor Plate | Mild Steel |

Installations. Contact us to discuss the availability of material options.

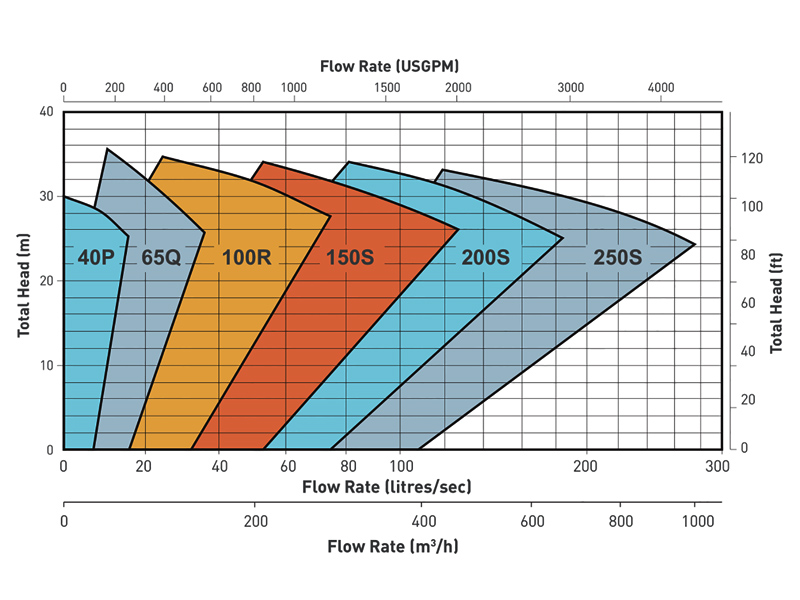

Performance Curve

Dimension

| Model | Length (mm) | ||||||||||||||||

| A | B | C | D | E | F | G | H | J | K | L | M | N | P | Q | R | S | |

| 40P | 137 | 285 | 153 | 900* 1200 |

380 | 500 | 500 | 450 | 450 | 205 | 127 | 174 | 733 | 675 | 248 | 629 | 280 |

| 40PR | 140 | 265 | 175 | 380 | 500 | 500 | 450 | 450 | 205 | 127 | 174 | 733 | 675 | 248 | 629 | 280 | |

| 65Q | 227 | 399 | 231 | 900 1200* 1500 |

492 | 680 | 680 | 620 | 620 | 285 | 178 | 265 | 898 | 794 | 290 | 681 | 350 |

| 65QR | 230 | 380 | 260 | 498 | 680 | 680 | 620 | 620 | 285 | 178 | 265 | 898 | 794 | 290 | 681 | 350 | |

| 100R | 260 | 538 | 317 | 1200 1500* 2100 |

662 | 1000 | 870 | 800 | 930 | 400 | 229 | 393 | 1141 | 1020 | 416 | 960 | 350 |

| 100RR | 266 | 535 | 332 | 668 | 1000 | 870 | 800 | 930 | 400 | 229 | 393 | 1141 | 1020 | 416 | 960 | 350 | |

| 150S | 390 | 670 | 365 | 1500 800* 2100 |

875 | 1100 | 1100 | 1030 | 1030 | 500 | 280 | 475 | 1311 | 1200 | 476 | 1011 | 350 |

| 150SR | 395 | 670 | 400 | 883 | 1100 | 1100 | 1030 | 1030 | 500 | 280 | 475 | 1311 | 1200 | 476 | 1011 | 350 | |

| 200S | 450 | 805 | 440 | 1800 2100* 2400 |

878 | 1300 | 1200 | 1100 | 1200 | 600 | 343 | 550 | 1313 | 1300 | 476 | 1011 | 350 |

| 200SR | 450 | 805 | 440 | 878 | 1300 | 1200 | 1100 | 1200 | 600 | 343 | 550 | 1313 | 1300 | 476 | 1011 | 350 | |

| 250S | 500 | 930 | 470 | 1800 2100* 2400 |

1000 | 1750 | 1450 | 1350 | 1650 | 700 | 406 | 685 | 1572 | 1750 | 561 | 1246 | 400 |

| 250SR | 500 | 930 | 470 | 1000 | 1750 | 1450 | 1350 | 1650 | 700 | 406 | 685 | 1572 | 1750 | 561 | 1246 | 400 | |