SRN series Side Channel Pumps

Application Std:DIN 2501 std of Flange PN16

Remarks: We have been OEM for many brands from Europe and USA

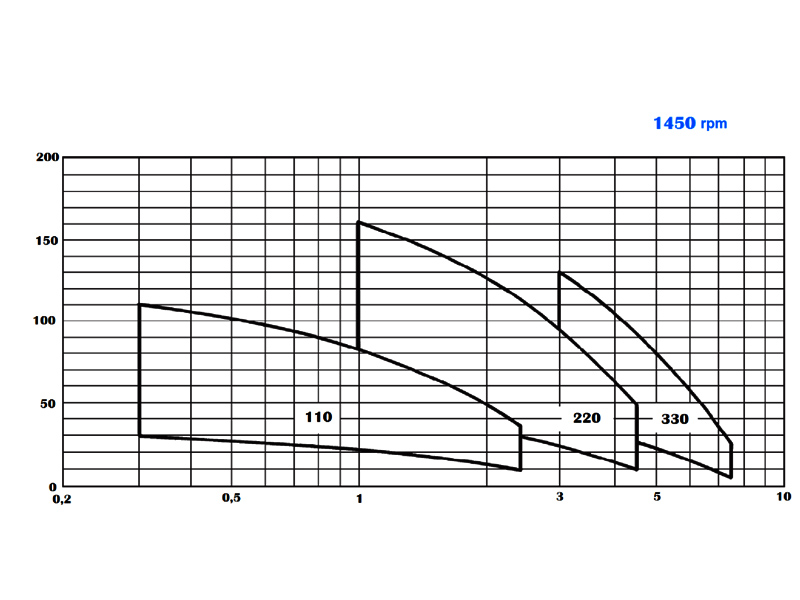

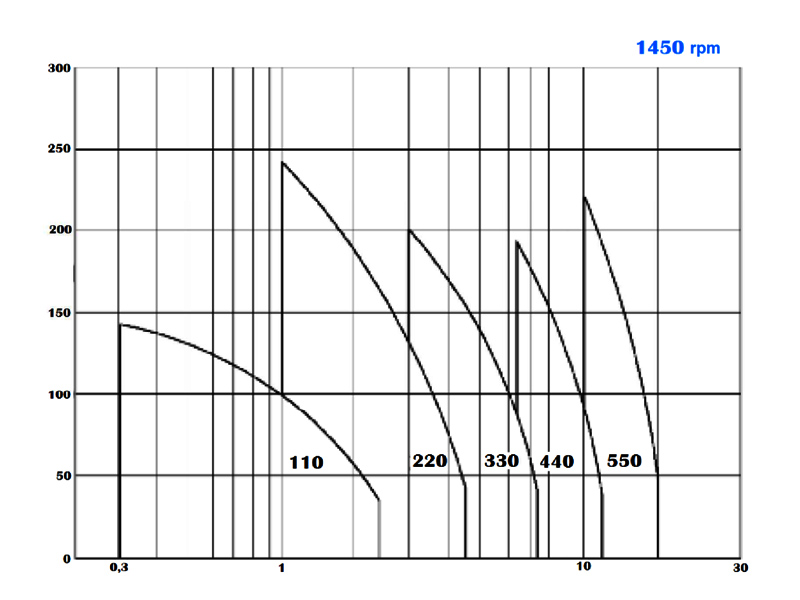

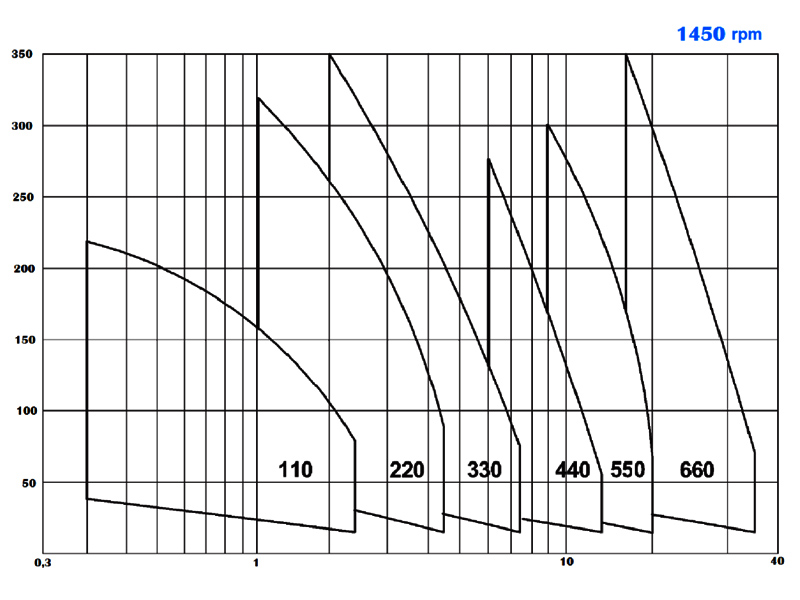

Performance Curve

Chemical and fine chemicals industries - Pharmaceutical industry - Cosmetic industry - Paper-making industry - Automo-tive industry - Metalworking industry - Integration companies - Transferring corrosive liquids or solvents - Tank unloading- General use...

| Material code | |||||

| Composant | 10 | 12 | 32 | 60 | 62 |

| Suction casing | Cast iron FT25 | Cast iron FT25 | SS 316L | Cast iron GS | Cast iron GS |

| Discharge casing | Cast iron FT25 | Cast iron FT25 | SS 316L | Cast iron GS | Cast iron GS |

| Stage casing | Cast iron FT25 | Cast iron FT25 | Duplex-1.4470 | Cast iron GS | Cast iron GS |

| Side Channel casing | Cast iron FT25 | Cast iron FT25 | Duplex-1.4470 | Cast iron GS | Cast iron GS |

| Foot | Cast iorn GS | Cast iorn GS | Cast iron GS | Cast iron GS | Cast iron GS |

| Shaft | SS 420 | SS 420 | SS 316Ti | SS 420 | SS 420 |

| Impeller | Cu Zn 40 AI 1 | Z20CN17.2M | SS 316Cb | Cu Zn 40 AI 1 | Z20CN17.2M |

| Bearing support | Cast iorn FT20 | Cast iorn FT20 | Cast iorn FT20 | Cast iorn FT20 | Cast iorn FT20 |

| Bearing cover open | Cast iorn FT20 | Cast iorn FT20 | Cast iorn FT20 | Cast iorn FT20 | Cast iorn FT20 |

| Bearing cover closed | Cast iorn FT20 | Cast iorn FT20 | Cast iorn FT20 | Cast iorn FT20 | Cast iorn FT20 |

| Casing gaskets | Teflon | Teflon | Teflon | Teflon | Teflon |

| Bearing bush | Bronze | Carbon | Carbon | Bronze | Bronze |

Standardised mechanical seal ( DIN 24960 ) Simple, double back to back, tandem or quenched assembly Non-compensated for outlet pressures less than 16 bar or compensated for pressures above . Friction face: Silicon carbide on carbon with the possibility to change on request O-ring material: According to the type of liquid conveyed, we'll adapt the type of O-ring

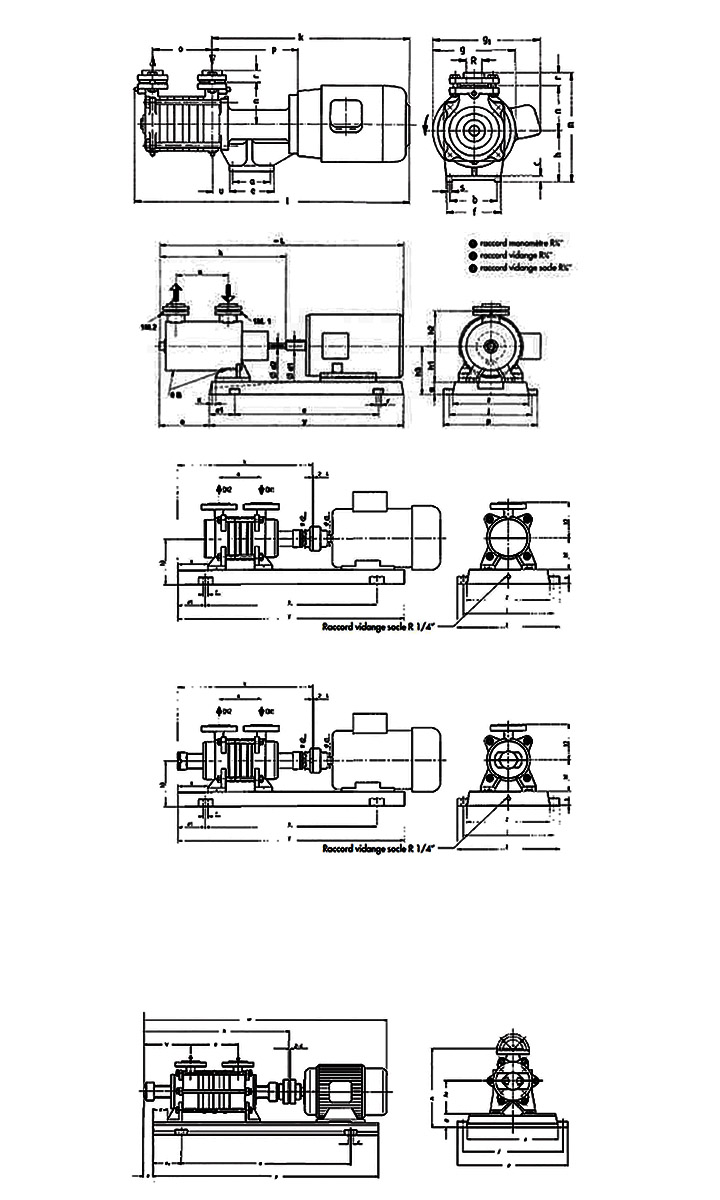

OVERALL DIMENSIONS

Applications & Industries

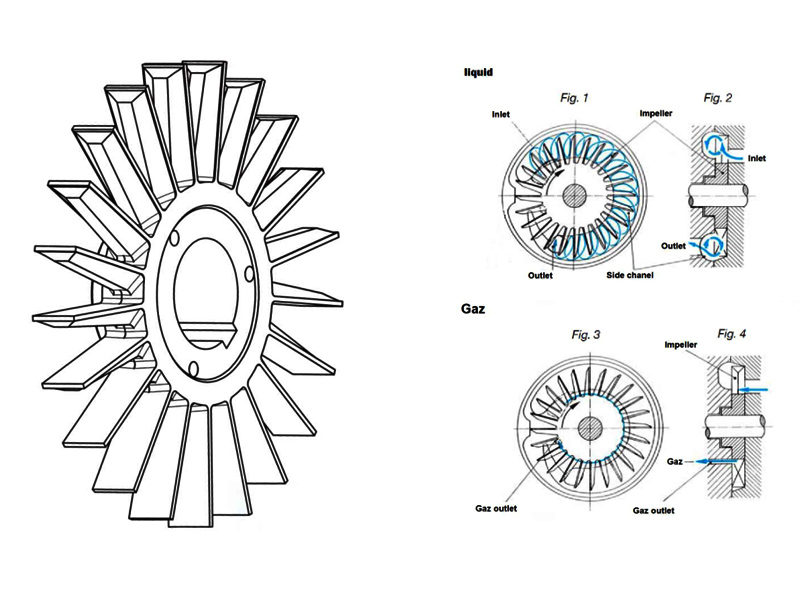

• For all applications where a self-priming pump is required. The pump is adapted for conveying clean, contaminat-ed liquids or dissolved gases (or not), which do not contain abrasive substances .

• Supplying heaters, construction of installations, chemical and petrochemical industries, machine building, ship building, agriculture, and residential solution for irrigation/watering and drainage.

Features

• The pumps come with oval counter flanges with threaded holes in 1"", 1¼" and 1½"

• Maximum total head between 110 and 160 mCI since the pump is limited to 16 bar and 7.5 m 3 /h.

Applications & Industries

• For all applications where a self-priming pump is required. The pump is adapted for conveying clean, contami-nated liquids or dissolved gases (or not), which do not contain abrasive substances.

• Supplying heaters, construction of installations, chemical and petrochemical industries, machine building, ship building, agriculture, and residential solution for irrigation/watering and drainage.

Features

• Pumps come with one block (ZS_SFH...W) or two blocks (ZS_SFH...WW)

• Maximum total head between 140 and 240 mCI since the pump is limited to 25 bar and 20 m 3 /h.

Applications

• The pumps in this series are made of standard, interchangeable hydraulic parts. They have a consistent perfor-mance level and comply with DIN 24254, which makes them interchangeable with other manufacturers' pumps.

• Combined with the ZS_SFH pumps, they can be used for difficult chemical and engineering applications.

Features

• Range of pumps complying with DIN 24254 or DIN/EN 734

• Maximum total head between 220 and 350 mCI since the pump is limited to 40 bar and 36 m 3 /h