Competitive Price for China High Quality Vertical Slurry Pump

To be a result of ours specialty and repair consciousness, our corporation has won an excellent reputation amongst customers all around the entire world for Competitive Price for China High Quality Vertical Slurry Pump, Never-ending improvement and striving for 0% deficiency are our two main quality policies. Should you need anything, never hesitate to get in touch with us.

To be a result of ours specialty and repair consciousness, our corporation has won an excellent reputation amongst customers all around the entire world for China Pump, Slurry Pump, We can give our clients absolute advantages in product quality and cost control, and we now have full range of molds from up to one hundred of factories. As product updating fast, we succeed in developing many high quality items for our clients and get high reputation.

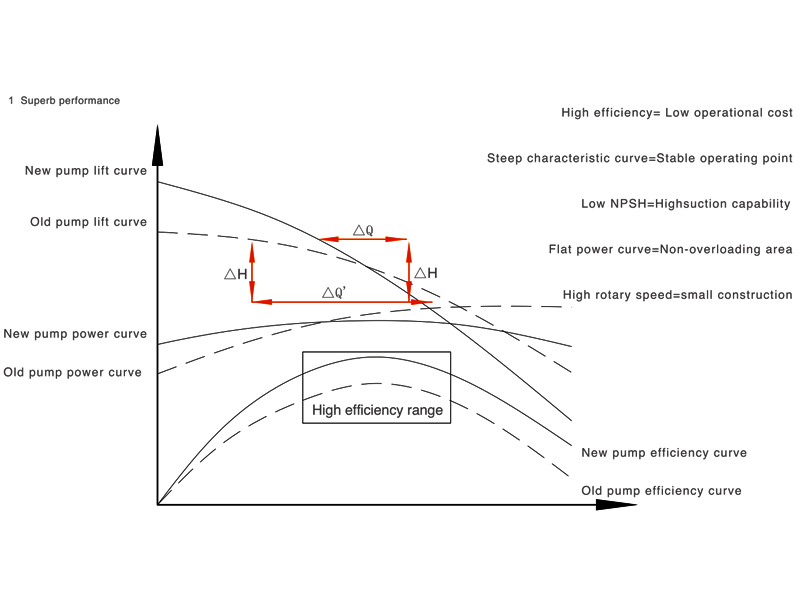

Features:

1.High Efficiency

Reduce power cost (connected horse power can now cost more than usd1000 per horse power)

2.Clog free operation

No blockage means minimum attention and minimum maintenance, except for periodic adjustments

3.Gentle Action

Prevents damage to delicate solids

4.Steep head-capacity curve

Minimizes interruptions in capacity, prevents motor overloads, and provides additional pressure to blow out plugs

5.Low NPSH requiremets

Hept to keep thick sludges and large solid moving as available suction head decreases. It also reduces installation costs.

6.Positive suction flow

Enables the pump to easily handle thick sludges

7.Externally adjustable liners

8.Abrasion-resistant construction

With 550 brinell, high chrome iron impeller and externally adjustable suction liner available.

Remarks: We have been OEM for many brands from Europe and USA

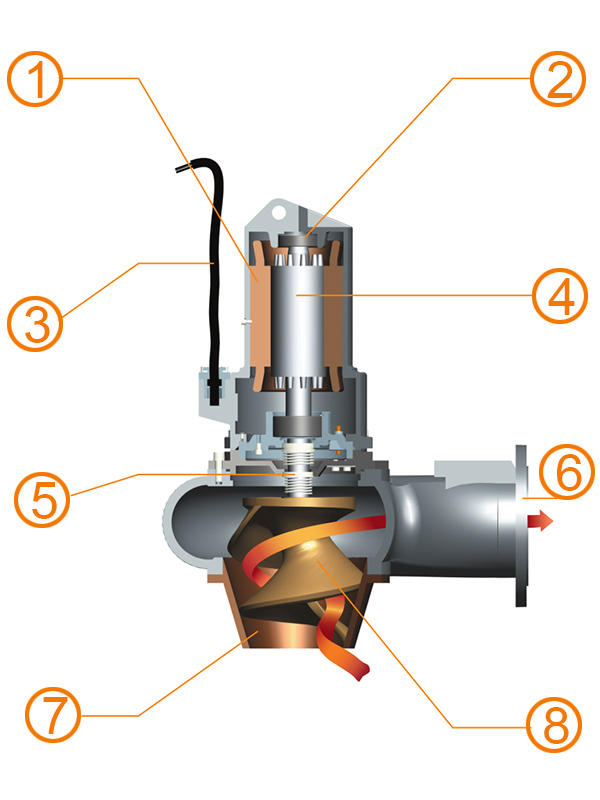

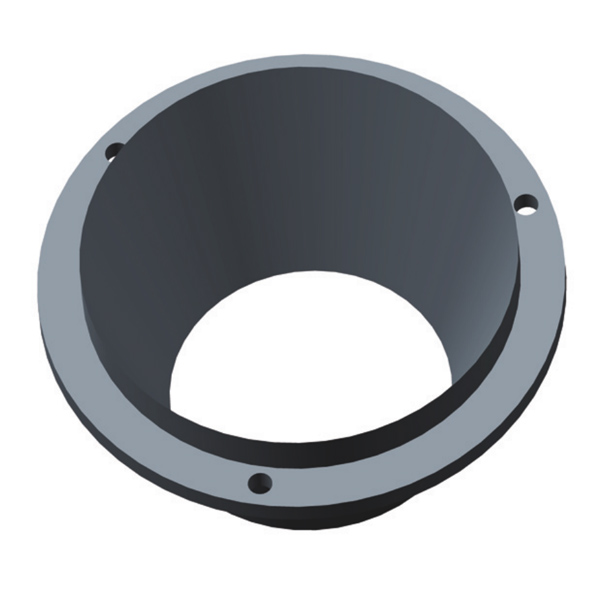

Sectional drawing

This series of screw centrifugal submersible sewage pump, introducing and absorbing domestic and foreign advanced technology, reasonable structure, superior performance. The squirrel cage motor operation mode of S1, the stator insulation class H (180 ℃), and has the anti-condensation device, each phase has equipped with overload protection device.

1、The stator winding of the motor (class H insulation, protection grade IP68)

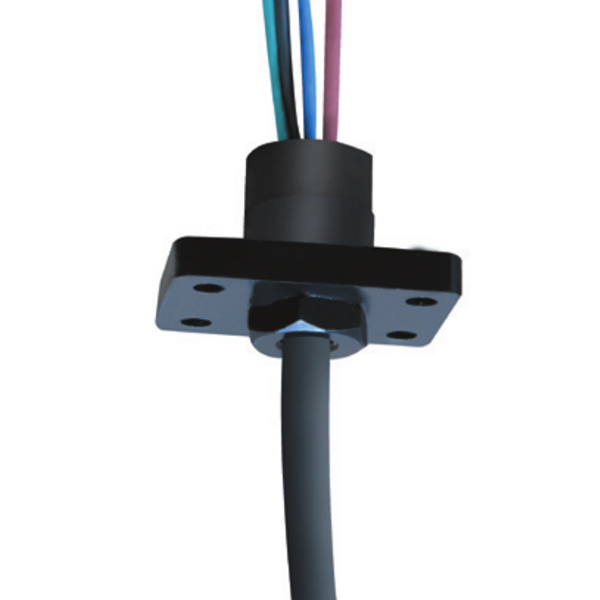

3、New type sealing material processing watertight cable

5、Anti winding compact design mechanical seal

2、High quality self lubricating bearing

4、Rotor assembly

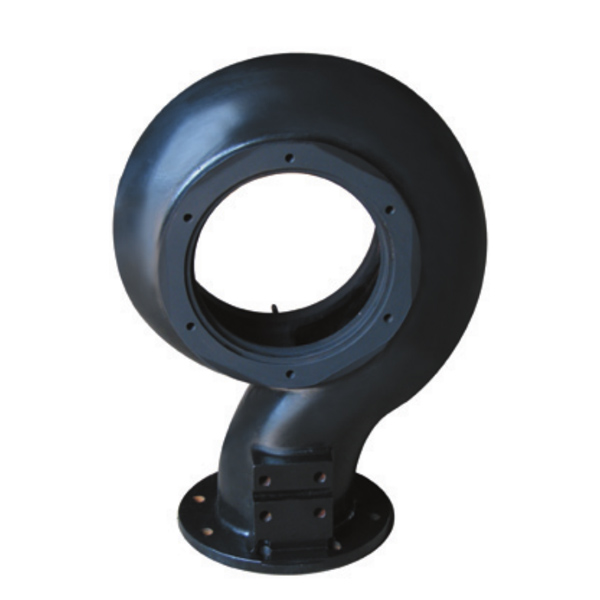

6、Wide channel volute

7、Seal ring

8、Screw centrifugal impeller

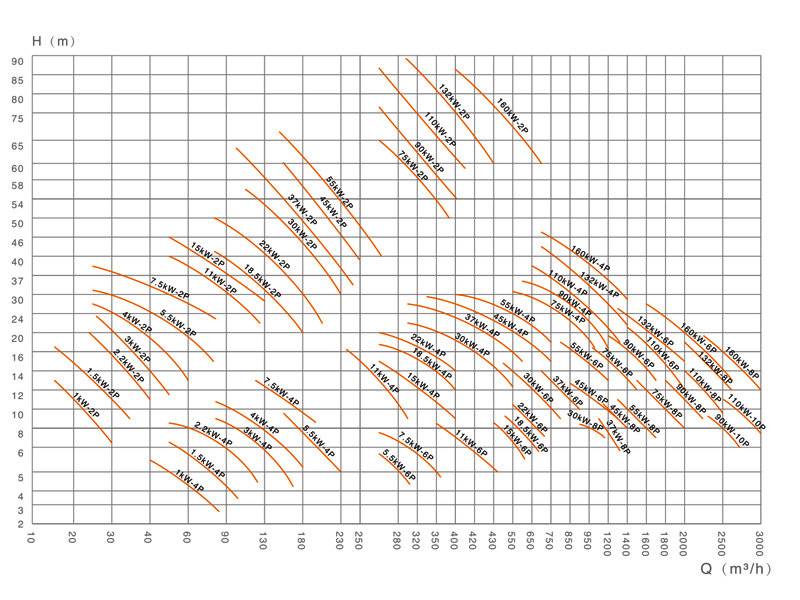

Performance Curve

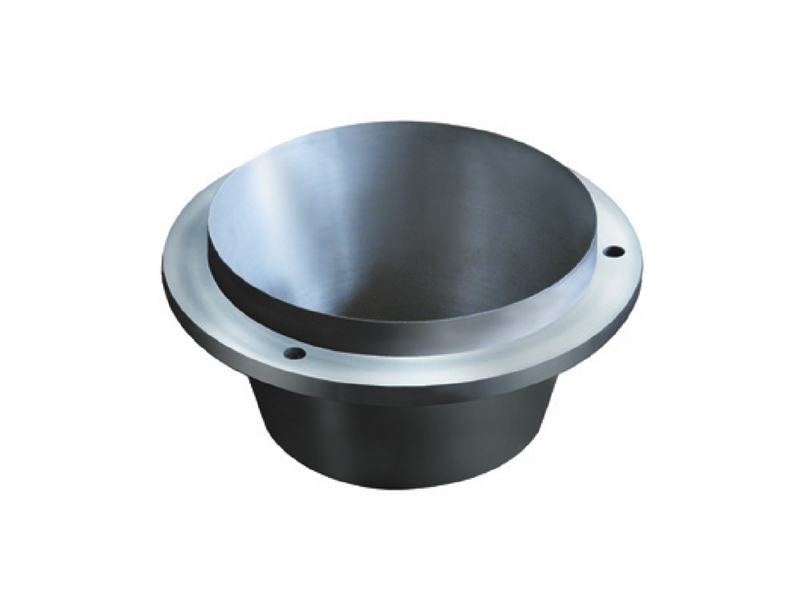

2 Replaceable casing wear liner

Screw centrifugal pump can be fitted optionally with a wear liner , this is ideal for abrasive process applications .when worn ,liners can be replaced at a fraction of the cost of replacing the entire casing

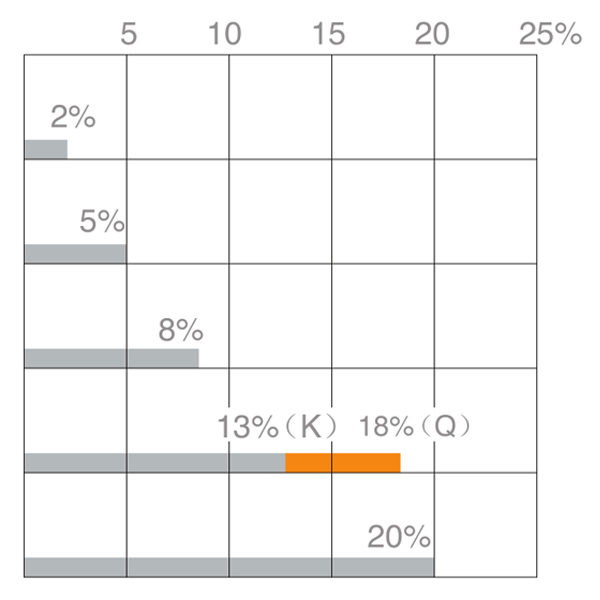

3 Dry solid scapacity of various pump types

• Multivane centrifugal

• Single or double vane centrifugal

• Vortex

• Screw centrifugal

• Archimedes screw, progressive cavity