Factory Cheap Pit Dewatering Pumps - BKD mono screw pump – Beken

Factory Cheap Pit Dewatering Pumps - BKD mono screw pump – Beken Detail:

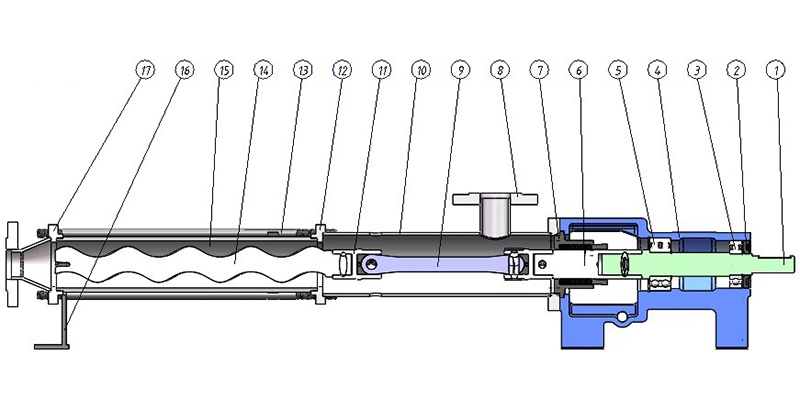

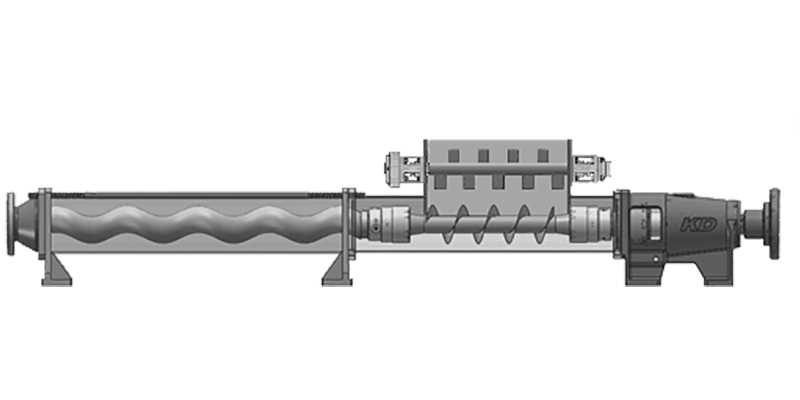

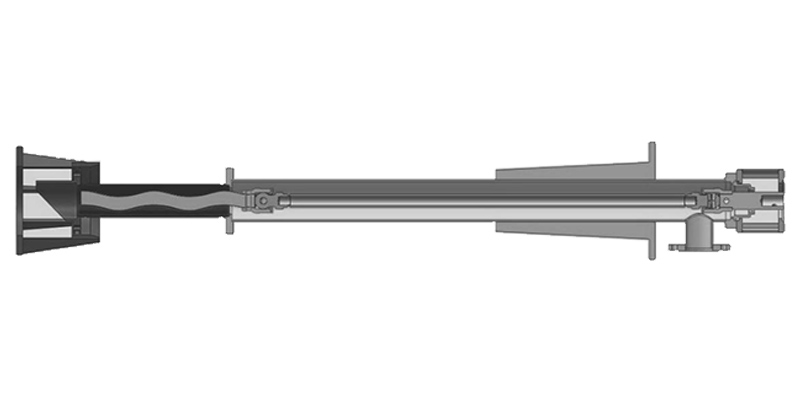

BKD Mono screw pump

| item | name | item | Name | item | Name |

| 1 | Shaft | 7 | Gland packing | 13 | Bar |

| 2 | Oil seal | 8 | Suction flange | 14 | Rotor |

| 3 | Bearing | 9 | Connected pole | 15 | Stator |

| 4 | Bearing housing | 10 | Suction chamber | 16 | Support |

| 5 | Heavy duty bearing | 11 | Cardan joint | 17 | Replease chamber |

| 6 | Connected shaft | 12 | Front flange |

1.Wide flow and pressure range: maximum flow up to 400m /h, conventional pressure up to 4.8mpa, special design pressure up to 10MPa

2.High viscosity is up to 1000000 cm.

3.The maximum suction is up to 7.5 meters.

4.The surface roughness of stator and stator core die has reached 0.4, which is the highest level in the industry, ensuring the surface roughness and reducing friction.

A

B

C

D

E

F

G

A

B

C

D

E

F

G

Application

Characteristic parameter

| maximum pump pressure | 12.0 MPa | Determined by the delivery process system, choose the pump series. |

| maximum working pressure | 10MPa | |

| maximum vacuum degree | 0.085MPa | Depending on the operating conditions, medium physical characteristics, pump series, etc. |

| maximum temperature pump medium allowed | 150℃ | Depends on the pump medium, the stator material structure. |

| mPas | 1000000cp | pump medium and pump speed and specifications. |

| maximum allowable solid content | 60% | pump specifications and solid characteristics and size and other factors. |

| maximum allowable gas content | 1:50 | volume of the gas in the standard state is related to the pressure of the suction chamber. |

Material combination

| number | name | Instruction | ||

| 1 | model | BKD series single screw pump, V for vertical pump, H for hopper pump, horizontal ellipsis not standard; Z is a directly connected structure, bearing structure is not standard. | ||

| 2 | Series Specifications | 102,103,104,107,108,110,112,115,118,121,125,129,130。 | ||

| 3 | Lead code | According to the lead property, it can be divided into L (long lead), N (ordinary lead) and S (short lead) subseries. | ||

| 4 | Flow | 400m3/h。 The maximum flow is 400m3/h. |

||

| 5 | pressure | The normal working pressure is 4.8mpa, and the special design can reach 10MPa. | ||

| 6 | material combination | · rotor | stator | Flow passage components |

| 40Cr | NBR | 40Cr/45 | ||

| 1Cr18Ni9Ti | NBR | 1Cr18Ni9Ti/304 | ||

| 304 | food-rubber | 304 | ||

| 304 | EPDM | 304 | ||

| 1Cr18Ni9Ti | EPDM | 1Cr18Ni9Ti/304 | ||

| 45 | FBR | 45 | ||

| 1Cr18Ni9Ti | FBR | 1Cr18Ni9Ti/304 | ||

| 2Cr13 | NBR | 1Cr18Ni9Ti/2Cr13 | ||

| 316L | NBR | 316L/304 | ||

| S31803 | FBR | S31803/316L | ||

1.According to the wear of the choice of pump speed

2.Special cases of the specific medium and its wear characteristics are given in the table. Please note that the characteristics of the medium vary with its concentration and temperature.

3.When the larger the size of the pump, the speed should be selected lower.

| Abrasiveness | Medium | Revolving speed |

| No | Water, lubricating oil, soapy water, blood, glycerin, etc. | 400-1000(rpm) |

| Ordinary | Heavy oil, municipal sewage, mud, suspension, industrial wastewater, paint pigment, paper pulp, mortar, food seasoning products, etc. | 200-400(rpm) |

| Serious | Super heavy oil, limestone cement slurry, clay, clay, coal water slurry, dehydrated sludge, glass glue, catalyst slurry, etc. | 50-200(rpm) |

| medium mucus | 1~1000(cst) | 1000~10000(cst) | 10000~100000(cst) | 100000~500000(cst) |

| revolving speed | 400~1000(rpm) | 200~400(rpm) | <200(rpm) | <100(rpm) |

| Rubber's character | NBR | FPM | EPDM |

| Maximum temperature | +100℃ | +150℃ | +120℃ |

| abrasive resistance | ○ | ○ | ● |

| ageing resistance | ● | ○ | ○ |

| ozone resistance | × | ○ | ○ |

| Steam resistance | ● | ○ | ○ |

| flame resistance | ● | ○ | ○ |

○:Premium ●:nice △:ordinary ×:no

| Adaptability | NBR | FPM | W.NBR | EPDM |

| kerosene | ● | ● | ● | × |

| diesel | ● | ● | ● | × |

| Ammonium chloride | × | △ | × | × |

| Ketone containing materials | × | × | × | ● |

| Alcohol containing materials | ● | ● | ● | ● |

| Fatty materials | × | × | × | ● |

| Materials containing ether | × | × | × | ● |

| Slurry | ● | △ | ● | ● |

| phosphoric acid | △ | △ | △ | ● |

| sodium carbonate | ● | × | ● | ● |

| Furfural | △ | △ | △ | ● |

| Benzene 100 | × | ● | × | × |

| Acetone | × | × | × | ● |

| inseed oil | ● | ● | ● | ● |

| carbon disulfide | × | ● | × | × |

| ethyl alcohol | ● | ● | ● | △ |

| Water | ● | ● | ● | ● |

| vegetable oil | ● | ● | ● | △ |

| mineral oil | ● | ● | ● | × |

| ammonium hydroxide | ● | × | ● | △ |

| aromatic solvent | × | ● | × | × |

| concentrated base | ● | × | ● | ● |

| aqua fortis | × | △ | × | × |

| glacial acetic acid | ● | ● | ● | × |

| dilute sulphuric acid | ● | ● | ● | ● |

| oil of vitriol | × | ● | × | △ |

| HCL | ● | ● | × | ● |

| concentrated hydrochloric acid | ● | ● | ● | ● |

| Hot water | △ | × | △ | ● |

| gasoline | ● | ● | ● | × |

| methylbenzene | × | ● | × | × |

| xylene | × | ● | × | × |

Note: the medium in the table is the qualitative condition of some common medium. If you have special medium condition or special requirement, please contact us.

0.6MPa

| 0.6MPa | |||||||

| L series | 100rpm Qth (m³/h) |

Speed(max) (rpm) |

Flow (m³/h) |

Shaft power (Kw) | Ordinary speed (rpm) | Flow (m³/h) |

Shaft power(Kw) |

| 102 | 0.11 | 2200 | 1.7 | 0.7 | 1450 | 1.1 | 0.5 |

| 103 | 0.32 | 1650 | 3.7 | 1.6 | 1100 | 2.4 | 1.1 |

| 104 | 0.93 | 1050 | 7 | 2.5 | 700 | 4.5 | 1.7 |

| 107 | 2.62 | 750 | 14 | 5.1 | 550 | 10 | 3.8 |

| 108 | 4.35 | 650 | 20.9 | 7.2 | 450 | 14.1 | 5 |

| 110 | 7.38 | 550 | 30.1 | 10.3 | 400 | 21.3 | 7.5 |

| 112 | 12.26 | 450 | 43.1 | 13.9 | 300 | 28 | 9.3 |

| 115 | 20.61 | 350 | 56.3 | 18.1 | 250 | 39.2 | 13 |

| 118 | 34.62 | 300 | 81 | 26.1 | 200 | 52.6 | 17.5 |

| 121 | 57.99 | 250 | 118.9 | 34.7 | 180 | 82.5 | 23.6 |

| 125 | 97.64 | 225 | 180.2 | 48.9 | 160 | 123.4 | 35.6 |

| 129 | 166.11 | 200 | 272.4 | 72.8 | 140 | 183.7 | 50.2 |

| 130 | 257.02 | 175 | 368.9 | 96.6 | 120 | 243.7 | 62.5 |

1.2MPa

| 1.2MPa | |||||||

| N series | 100rpm Qth(m³/h) | Speed(max) (rpm) | Flow (m³/h) |

Shaft power (Kw) | Ordinary speed (rpm) | Flow (m³/h) |

Shaft power(Kw) |

| 102 | 0.06 | 2200 | 0.9 | 0.6 | 1450 | 0.6 | 0.4 |

| 103 | 0.16 | 1600 | 1.9 | 1.2 | 1100 | 1.2 | 0.8 |

| 104 | 0.46 | 1050 | 3.5 | 2.2 | 700 | 2.2 | 1.4 |

| 107 | 1.31 | 750 | 7.3 | 3.9 | 550 | 5.1 | 2.8 |

| 108 | 2.2 | 650 | 10.6 | 5.6 | 450 | 6.9 | 3.8 |

| 110 | 3.69 | 550 | 16.1 | 8 | 400 | 10.6 | 5.5 |

| 112 | 6.23 | 450 | 22.2 | 11 | 300 | 13.5 | 6.9 |

| 115 | 10.44 | 350 | 28.9 | 14.4 | 250 | 18.8 | 9.6 |

| 118 | 17.54 | 300 | 43.2 | 20.3 | 200 | 26.7 | 12.9 |

| 121 | 29.41 | 250 | 60.3 | 28.3 | 180 | 40.3 | 19.4 |

| 125 | 49.49 | 225 | 94.7 | 42.1 | 160 | 62.6 | 28.6 |

| 129 | 83.05 | 200 | 141.2 | 62.8 | 140 | 91.9 | 41.9 |

| 130 | 128.5 | 175 | 191.2 | 85 | 120 | 121.8 | 55.6 |

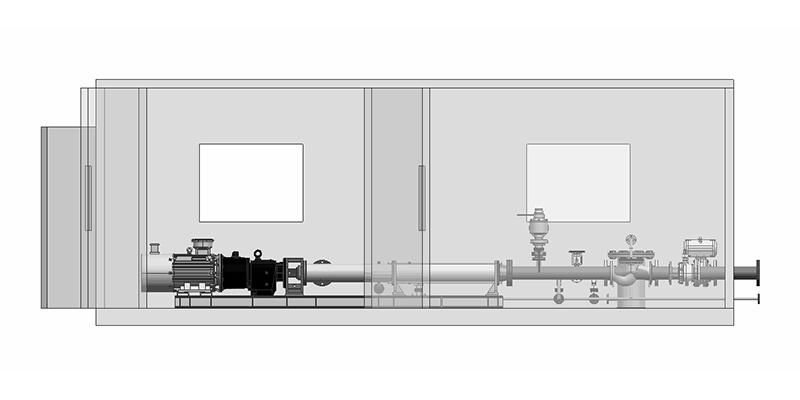

Product detail pictures:

Related Product Guide:

Factory Cheap Pit Dewatering Pumps - BKD mono screw pump – Beken, The product will supply to all over the world, such as: , , ,