Fast delivery China Factory Air Operated Non-Metallic Models Pneumatic Diaphragm Pump

To constantly improve the management system by virtue of the rule of "sincerely, good faith and quality are the base of enterprise development", we widely absorb the essence of related products internationally, and constantly develop new products to meet the demands of customers for Fast delivery China Factory Air Operated Non-Metallic Models Pneumatic Diaphragm Pump, On account of superior excellent and aggressive rate , we will be the sector leader, make sure you don’t hesitate to contact us by cellular phone or email, if you're fascinated in almost any of our items.

To constantly improve the management system by virtue of the rule of "sincerely, good faith and quality are the base of enterprise development", we widely absorb the essence of related products internationally, and constantly develop new products to meet the demands of customers for China Pneumatic Diaphragm Pumps, Plastic Pneumatic Diaphragm Pumps, We've been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy you with our high-quality merchandise and perfect service . We also warmly welcome customers to visit our company and purchase our solutions.

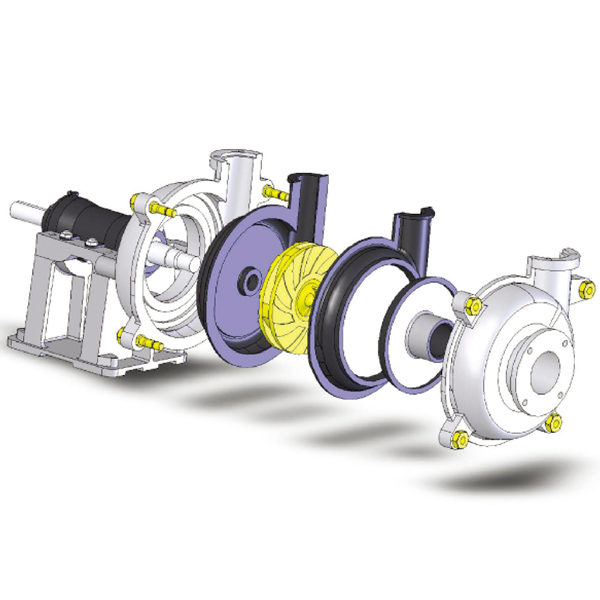

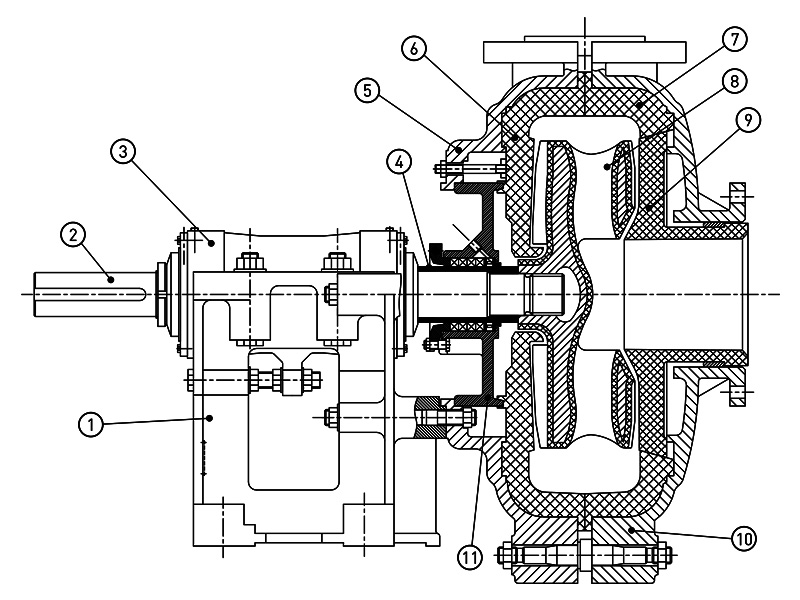

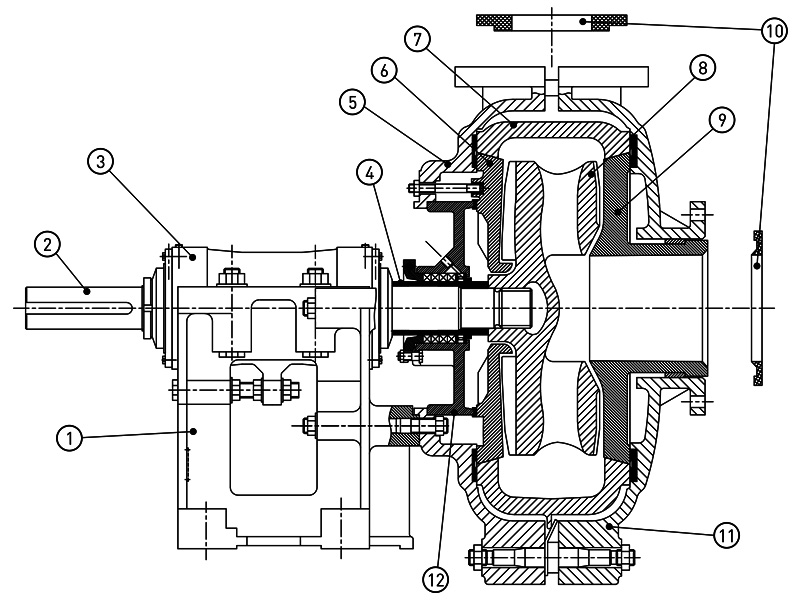

•Cartridge Bearing assembly and shaft

•The shaft is designed with a short overhand to

Reduce shaft deflection

Minimize vibration

•Provided with hardened shaft sleeve to protect the shaft

•Optional dimentionally interchangable heavy duty bearing cartridge assemblies.

•Cartridge assembly is retained on a one piece frame

•INPRO labyrinth seals standard for best-in-class bearing protection

Liners and Impellers for hard metal (WX) and elastomer lined (WXR) pumps have common dimensions and are interchangeable within the same pump size.

Frame supports the bearing cartridge which includes grease lubricated standard single row taper roller or Heavy Duty two row taper roller and parallet roller cylindrical bearings. Bearings are located on a large diameter shaft designed to minimize overhang and deflection.

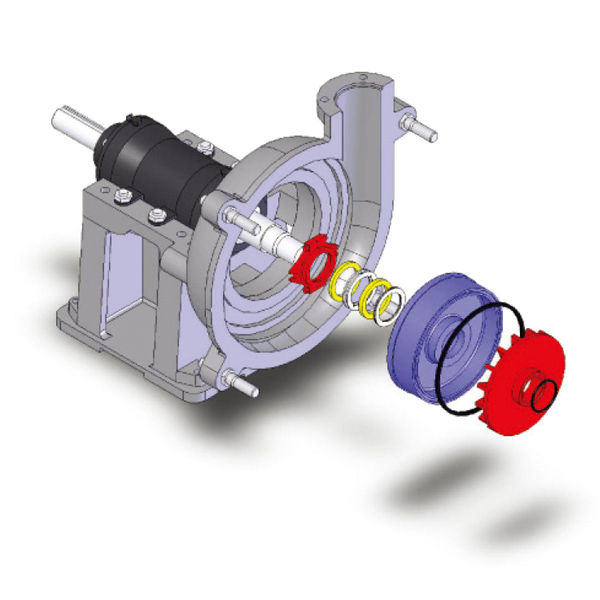

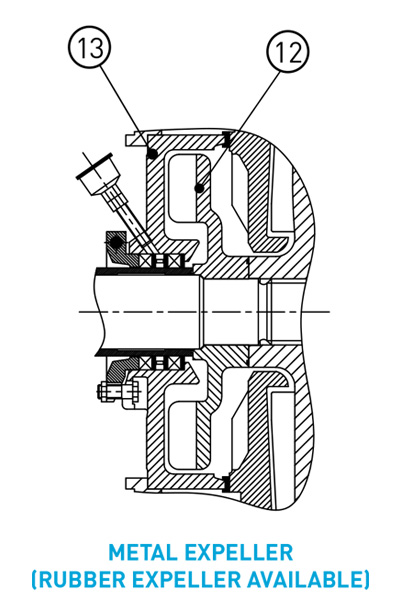

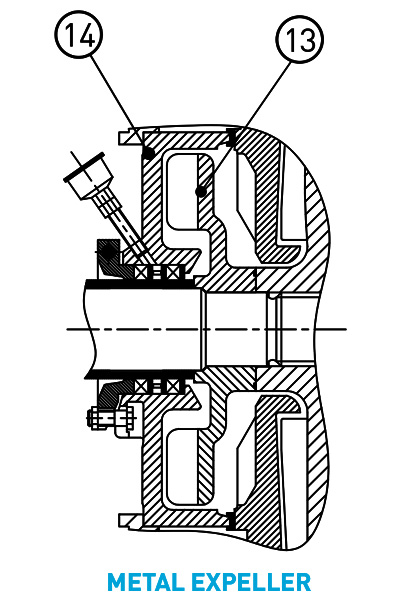

MULTIPLE SEALINGS OPTIONS

Standard gland seal (packed box with lantern ring) requires flush water.

Where suction conditions allow, Atlas’s expeller seal can eliminate the need to supply water to the stuffing box. Where high suction pressures or series pumping is desired other methods of sealing must be utilized.

Expeller and expeller ring are constructed from Hi-Chrome material.

Shaft sleeve material is 420 SS hardened to 550 Brinell to protect the shaft from wear.

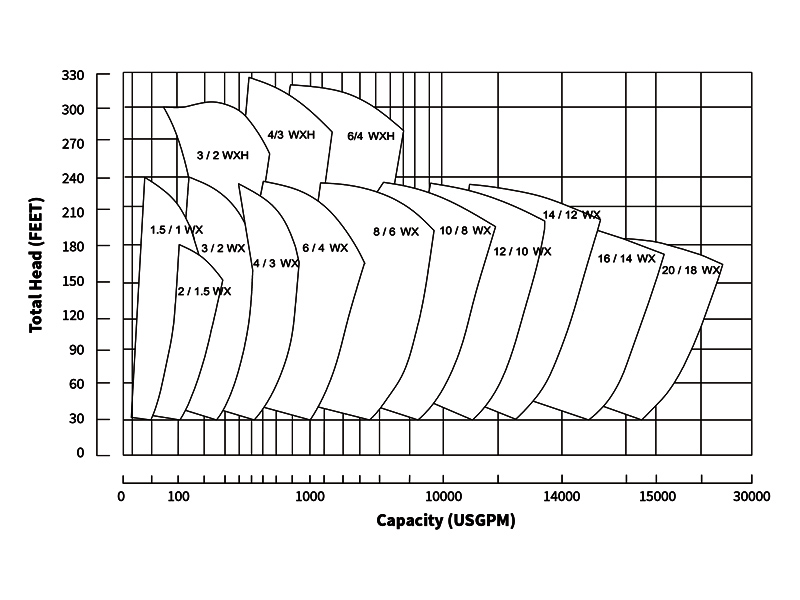

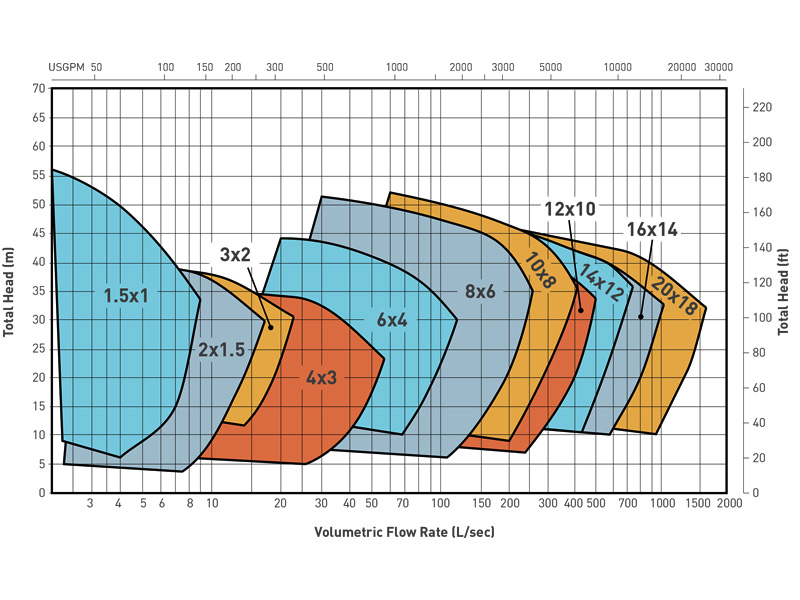

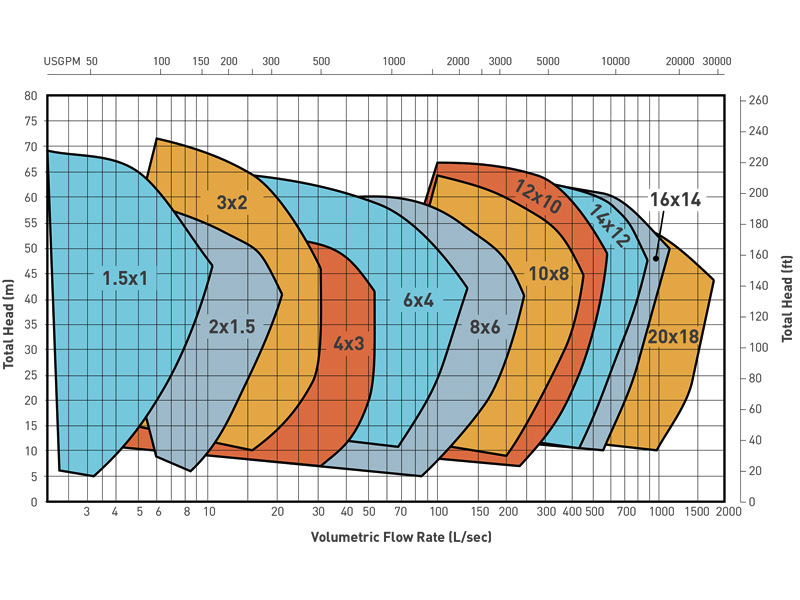

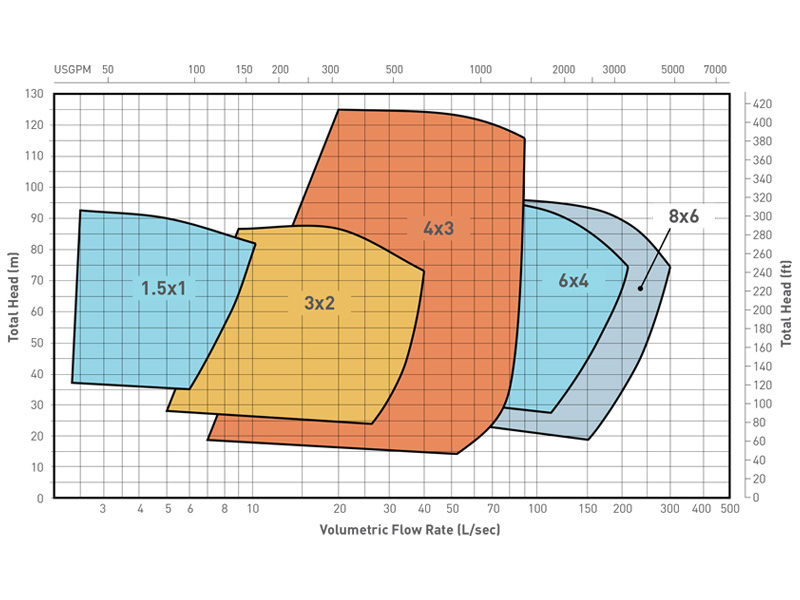

Hydraulic Coverage - 60HZ

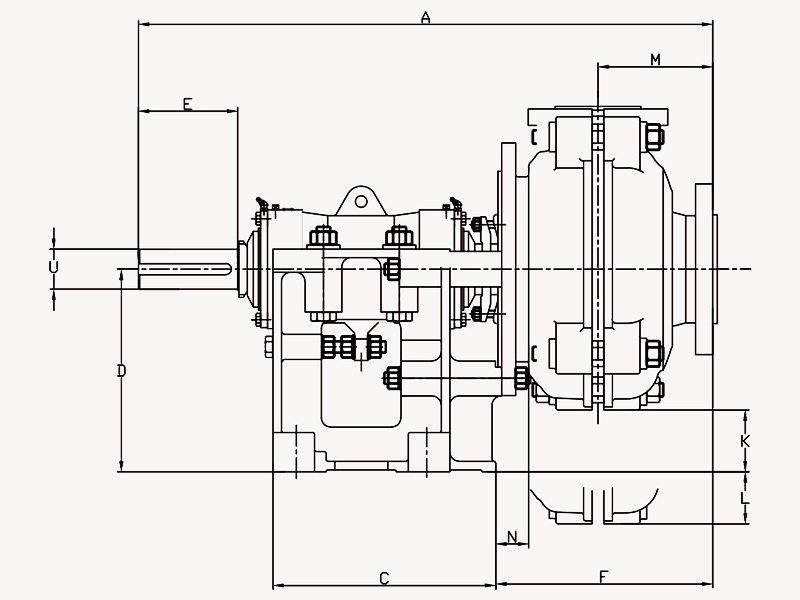

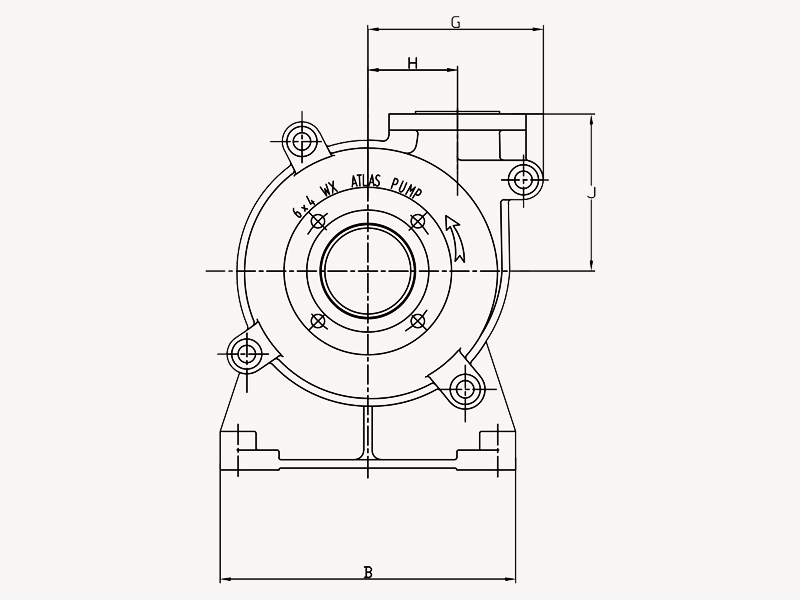

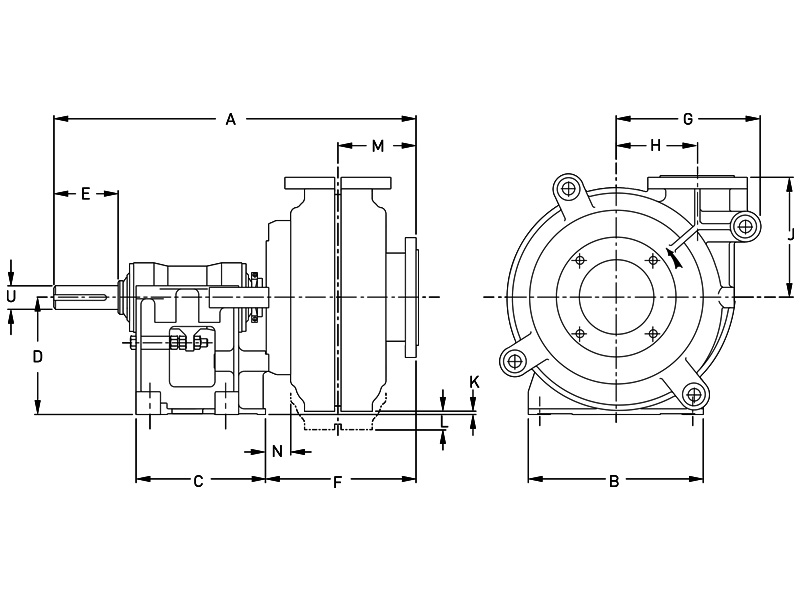

Dimensional drawing

| Size | A | B | C | D | U | Key Size |

E | F | G | H | J | K | L | M | N | Wt/LBs | |

| Model | (in) | (in) | (in) | (in) | (mm) | (mm) | (in) | (in) | (in) | (in) | (in) | (in) | (in) | (in) | (in) | Metal | Elastomer |

| 1.5/1 BWX | 22.95 | 11.61 | 9.76 | 7.76 | 28 | 8X7 | 3.11 | 8.11 | 7.13 | 3.86 | 6.73 | 1.81 | * | 4.17 | 0.74 | 195 | 170 |

| 2/1.5 BWX | 23.45 | 11.61 | 9.76 | 7.76 | 28 | 8X7 | 3.09 | 8.54 | 7.99 | 4.49 | 7.24 | 1.31 | * | 4.65 | 0.86 | 345 | 260 |

| 3/2 CWX | 30.47 | 15.98 | 12.24 | 10 | 42 | 12X8 | 4.41 | 11.02 | 9.37 | 5.43 | 8.27 | 2.81 | * | 6.14 | 1.56 | 435 | 340 |

| 3/2 DWXH | 28.82 | 19.37 | 14.33 | 12.99 | 65 | 18X11 | 6.46 | 15.28 | 15.12 | 10 | 14.49 | * | 2 | 7.99 | 3.28 | 1550 | * |

| 4/3 CWX | 33.62 | 15.98 | 12.24 | 10 | 42 | 12X8 | 4.76 | 14.13 | 11.5 | 5.87 | 10.31 | 0.79 | * | 7.56 | 2.83 | 550 | 520 |

| 4/3 DWX | 37.6 | 19.37 | 14.33 | 12.99 | 65 | 18X11 | 6.46 | 13.62 | 11.5 | 5.87 | 10.31 | 3.93 | * | 7.56 | 2.83 | 700 | 640 |

| 4/3 EWXH | 48.82 | 24.49 | 17.64 | 17.99 | 80 | 22X14 | 8.74 | 19.37 | 19.37 | 12.99 | 17 | * | * | 9.76 | 3.12 | 2750 | * |

| 6/4 DWX | 40.2 | 19.37 | 14.33 | 12.99 | 65 | 18X11 | 6.46 | 16.69 | 15.98 | 9.02 | 13.31 | 0.43 | * | 8.62 | 2.57 | 1475 | 1000 |

| 6/4 EWX | 46.73 | 24.49 | 17.64 | 17.99 | 80 | 22X14 | 8.74 | 17.05 | 15.98 | 9.02 | 13.31 | 5.43 | * | 8.98 | 2.96 | 1950 | 1400 |

| 6/4 FWXH | 61.26 | 33.74 | 24.96 | 24.02 | 100 | 28X16 | 10.98 | 23.03 | 24.25 | 16.26 | 21.5 | 1.00 | * | 12.01 | 2.96 | 5575 | * |

| 8/6 EWX | 51.3 | 24.49 | 17.64 | 17.99 | 80 | 22X14 | 8.74 | 21.93 | 21.69 | 12.52 | 18.11 | * | 2.44 | 11.5 | 3.23 | 3300 | 2166 |

| 8/6 FWX | 59.7 | 33.74 | 25 | 24.02 | 100 | 28X16 | 10.98 | 21.22 | 21.69 | 12.52 | 18.11 | 3.54 | * | 11.97 | 2.56 | 4000 | 3066 |

| 10/8 FWX | 64.8 | 39.02 | 27.76 | 24.02 | 100 | 28X16 | 10.98 | 26.89 | 26.5 | 16.5 | 25 | * | 0.47 | 13.11 | 5.28 | 7040 | 5690 |

| 10/8 STWX | 68.98 | 45.28 | 30.71 | 25.59 | 120 | 32X18 | 11.02 | 27.24 | 26.5 | 16.5 | 25 | 1.06 | * | 13.15 | 5.63 | 8250 | 6900 |

| 12/10 FWX | 67.76 | 39.02 | 27.76 | 24.02 | 100 | 28X16 | 10.98 | 29.65 | 29.76 | 18.27 | 26.5 | * | 4.09 | 15 | 4.25 | 8290 | 6190 |

| 12/10 STWX | 71.5 | 45.28 | 30.71 | 25.59 | 120 | 32X18 | 11.02 | 30 | 29.72 | 18.27 | 26.5 | * | 2.56 | 15 | 4.6 | 9500 | 7400 |

| 14/12 FWX | 69.84 | 39.02 | 27.76 | 24.02 | 100 | 28X16 | 10.98 | 31.61 | 36.89 | 24.76 | 32.76 | * | 10.35 | 15.98 | 4.13 | 12890 | 9090 |

| 14/12 STWX | 73.74 | 45.28 | 30.71 | 25.59 | 120 | 32X18 | 11.02 | 31.97 | 36.89 | 24.76 | 32.76 | * | 8.82 | 15.98 | 4.48 | 14100 | 10300 |

| 16/14 TUWX | 91.34 | 57.48 | 41.34 | 35.43 | 150 | 36X20 | 13.78 | 37.52 | 41.26 | 25.98 | 35 | * | 3.31 | 17.76 | 6.56 | 22000 | * |

| 20/18 TUWX | 97.44 | 57.48 | 41.34 | 35.43 | 150 | 36X20 | 13.78 | 44.29 | 55.67 | 37.01 | 48.43 | * | 16.42 | 22.84 | 2.98 | 36440 | 27181 |

MATERIALS RUBBER LINED PUMPS

| No. | Part Description | Material Specification |

| 1 | Base | Cast Iron |

| 2 | Shaft | 4140 Hige Tensile Steel* |

| 3 | Bearing Assembly | Timkin(Cast Iron Body) |

| 4 | Shaft Sleeve | 420 Stainless Steel |

| 5 | Pump Casing | Cast Iron |

| 6 | Frame Plate Liner | Rubber |

| 7 | Cover Plate Liner | Rubber |

| 8 | Impellr | Rubber Coated High Tensile Steel |

| 9 | Throat Bush | Rubber |

| 10 | Cover Plate | Cast Iron |

| 11 | Stuffing Box | Cast Iron |

| 12 | Expeller | 27% Chrome White Iron |

| 13 | Expeller Ring | Natural Rubber |

| Bolts | Zinc Plated Steel | |

| O-rings | Nitrile Rubber | |

| Seals | Rubber |

MATERIALS METAL LINED PUMPS

| No. | Part Description | Material Specification |

| 1 | Base | Cast Iron |

| 2 | Shaft | 4140 Hige Tensile Steel* |

| 3 | Bearing Assembly | Timkin(Cast Iron Body) |

| 4 | Shaft Sleeve | 420 Stainless Steel |

| 5 | Pump Casing | Cast Iron |

| 6 | Frame Plate Liner | 27% Chrome White Iron |

| 7 | Volute Liner | 27% Chrome White Iron |

| 8 | Impellr | 27% Chrome White Iron |

| 9 | Throat Bush | 27% Chrome White Iron |

| 10 | Joint Rings | Rubber |

| 11 | Cover Plate | Cast Iron |

| 12 | Stuffing Box | Cast Iron |

| 13 | Expeller | 27% Chrome White Iron |

| 14 | Expeller Ring | Natural Rubber |

| Bolts | Zinc Plated Steel | |

| O-rings | Nitrile Rubber | |

| Seals | Rubber |

| Model | Dimensions (mm) | ||||||||||||||||

| A | B | C | D | Key Size |

E | F | G | H | J | K | L | M | N | U | Wt/LBs | ||

| 1.5/1 B | 583 | 295 | 248 | 197 | 8X7 | 79 | 206 | 181 | 98 | 171 | 46 | - | 106 | 19 | 28 | 88 | 77 |

| 1.5x1 C - HH | 759 | 406 | 311 | 254 | 12x8 | 121 | 306 | 270 | 194 | 254 | - | 11 | 121 | 66 | 42 | 318 | - |

| 2x1.5 B | 592 | 295 | 248 | 197 | 8X7 | 79 | 217 | 203 | 114 | 184 | 33 | - | 114 | 22 | 28 | 156 | 118 |

| 3x2 C | 768 | 406 | 311 | 254 | 12x8 | 121 | 280 | 238 | 138 | 210 | 71 | - | 151 | 40 | 42 | 197 | 154 |

| 3x2 D - HH | 986 | 492 | 364 | 330 | 18x11 | 164 | 389 | 384 | 254 | 368 | - | 51 | 203 | 83 | 65 | 750 | - |

| 4x3 C | 843 | 406 | 311 | 254 | 12x8 | 121 | 353 | 292 | 149 | 262 | 24 | - | 187 | 54 | 42 | 249 | 236 |

| 4x3 D | 943 | 492 | 364 | 330 | 18x11 | 164 | 353 | 292 | 149 | 262 | 100 | - | 187 | 52 | 65 | 318 | 290 |

| 4x3 E - HH | 1240 | 622 | 448 | 457 | 22x14 | 222 | 492 | 492 | 330 | 432 | - | 12 | 248 | 79 | 80 | 1250 | - |

| 6x4 D | 1021 | 857 | 364 | 330 | 18x11 | 164 | 424 | 406 | 229 | 338 | 11 | - | 219 | 65 | 65 | 669 | 454 |

| 6x4 E | 1178 | 622 | 448 | 457 | 28X16 | 222 | 433 | 406 | 229 | 338 | 138 | - | 219 | 75 | 80 | 885 | 635 |

| 6x4 F - HH | 1556 | 857 | 634 | 610 | 22X14 | 164 | 585 | 616 | 413 | 546 | - | 134 | 305 | 75 | 65 | 3420 | - |

| 8x6 E | 1302 | 1150 | 448 | 457 | 28X16 | 222 | 557 | 551 | 318 | 460 | - | 62 | 292 | 82 | 100 | 1497 | 982 |

| 8x6 F | 1507 | 991 | 635 | 610 | 28X14 | 279 | 539 | 551 | 318 | 460 | 90 | - | 292 | 65 | 80 | 1814 | 1390 |

| 8x6 T - HH | 2275 | 1150 | 1040 | 650 | 36x20 | 350 | 852 | 835 | 584 | 813 | - | 160 | 394 | - | 100 | 6900 | - |

| 10x8 F | 1646 | 991 | 705 | 610 | 28X16 | 279 | 683 | 673 | 419 | 635 | - | 12 | 333 | 134 | 150 | 3193 | 2581 |

| 10x8 ST | 1748 | 1150 | 780 | 650 | 32X18 | 280 | 692 | 673 | 419 | 635 | 27 | - | 333 | 143 | 100 | 3742 | 3130 |

| 12x10 F | 1721 | 991 | 705 | 610 | 28X16 | 279 | 753 | 756 | 464 | 673 | - | 104 | 381 | 108 | 100 | 3760 | 2808 |

| 12x10 ST | 1816 | 1150 | 780 | 650 | 32X18 | 280 | 762 | 755 | 464 | 673 | - | 65 | 381 | 117 | 120 | 4309 | 3357 |

| 14x12 F | 1772 | 991 | 705 | 610 | 28x16 | 279 | 803 | 937 | 629 | 832 | - | 263 | 406 | 105 | 100 | 5847 | 4123 |

| 14x12 ST | 1873 | 1460 | 780 | 650 | 32x18 | 280 | 812 | 937 | 629 | 832 | - | 224 | 406 | 114 | 120 | 6396 | 4672 |

| 16X14 TU | 2320 | 1460 | 1050 | 900 | 36x20 | 350 | 953 | 1048 | 660 | 889 | - | 84 | 451 | 167 | 150 | 9979 | - |

| 20X18 TU | 2475 | 1460 | 1050 | 900 | 36x20 | 350 | 1100 | 1420 | 940 | 1230 | - | 420 | 480 | 210 | 150 | 18864 | 15921 |